Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone

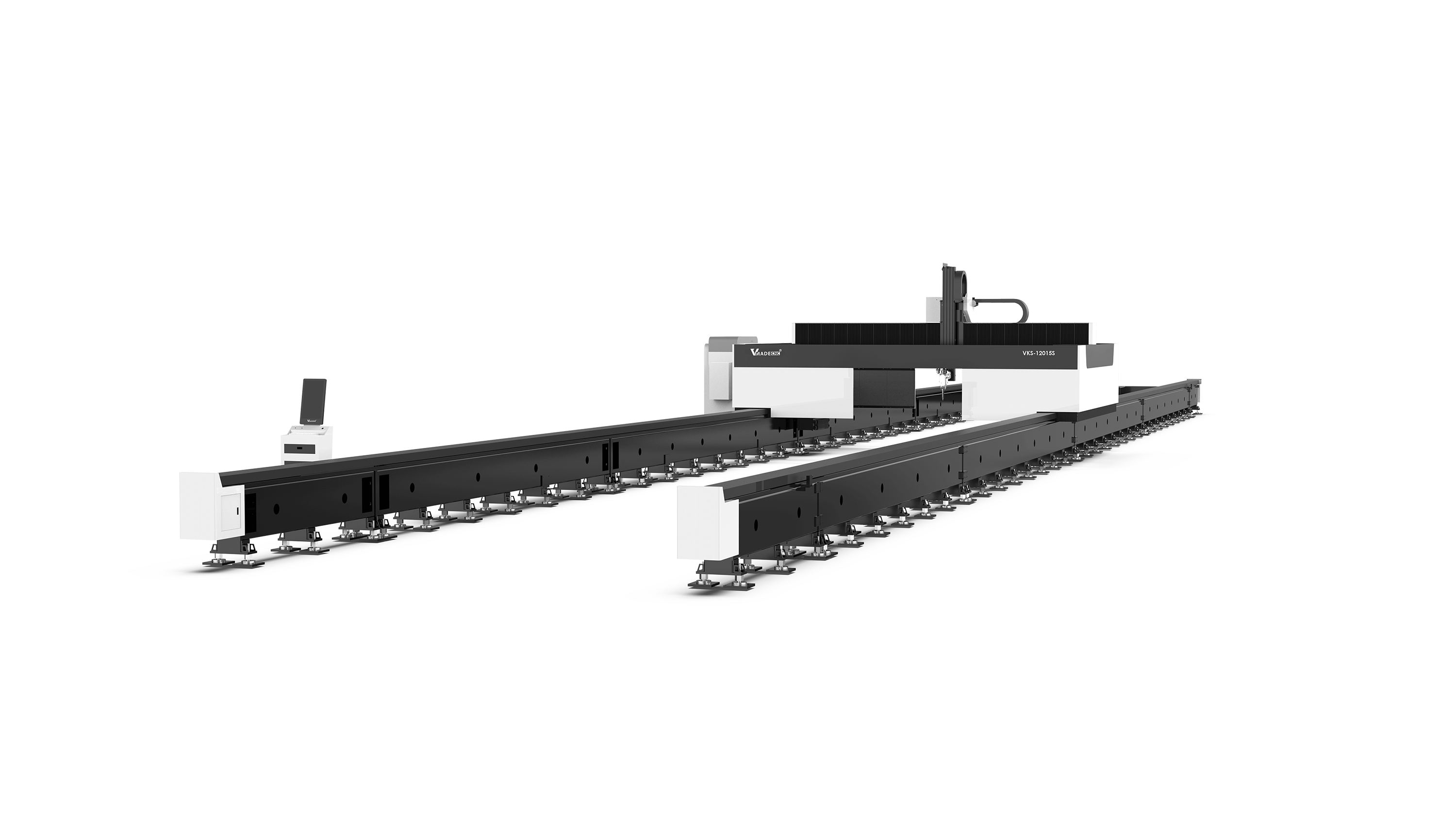

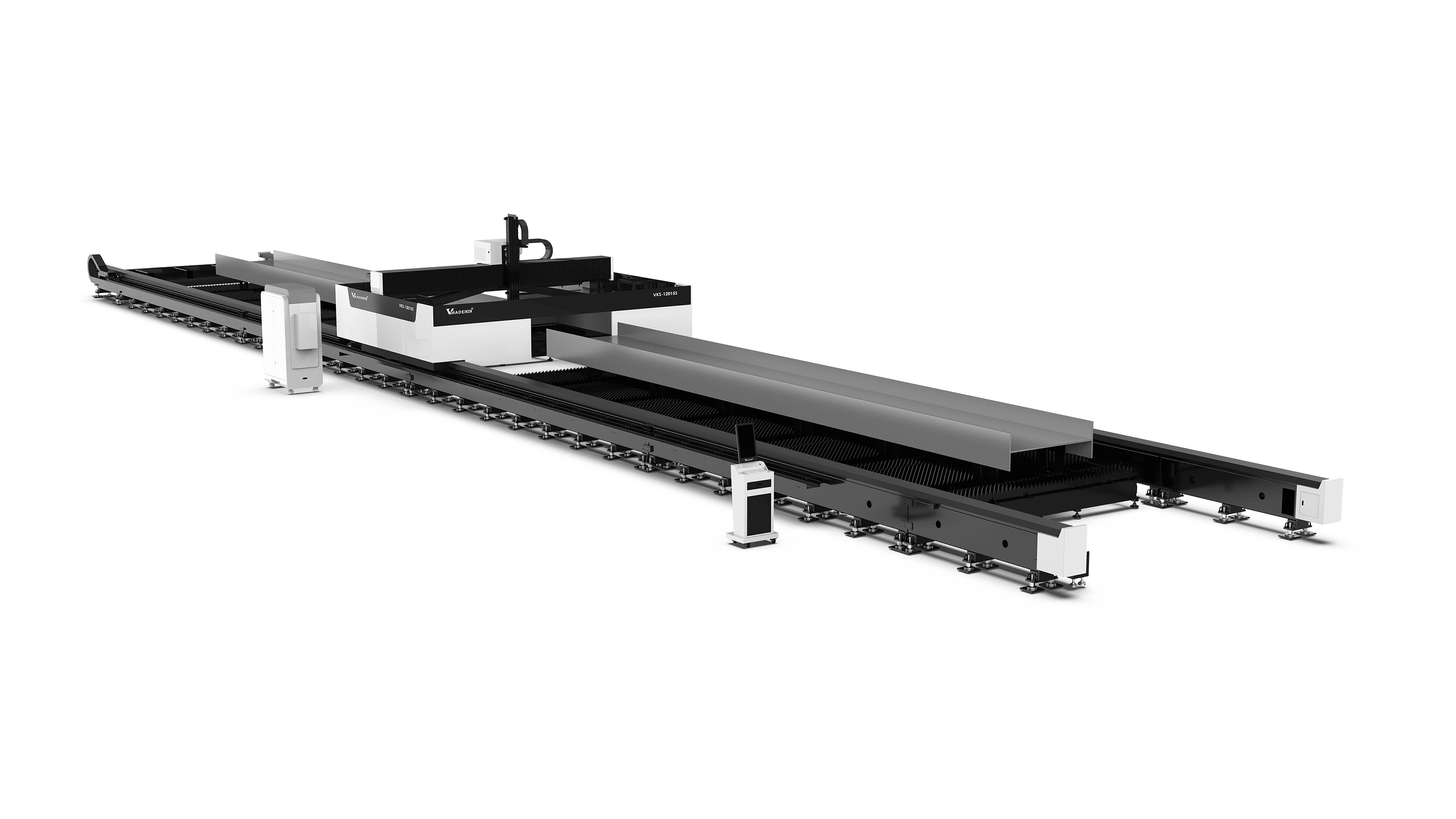

Standard - without cutting table

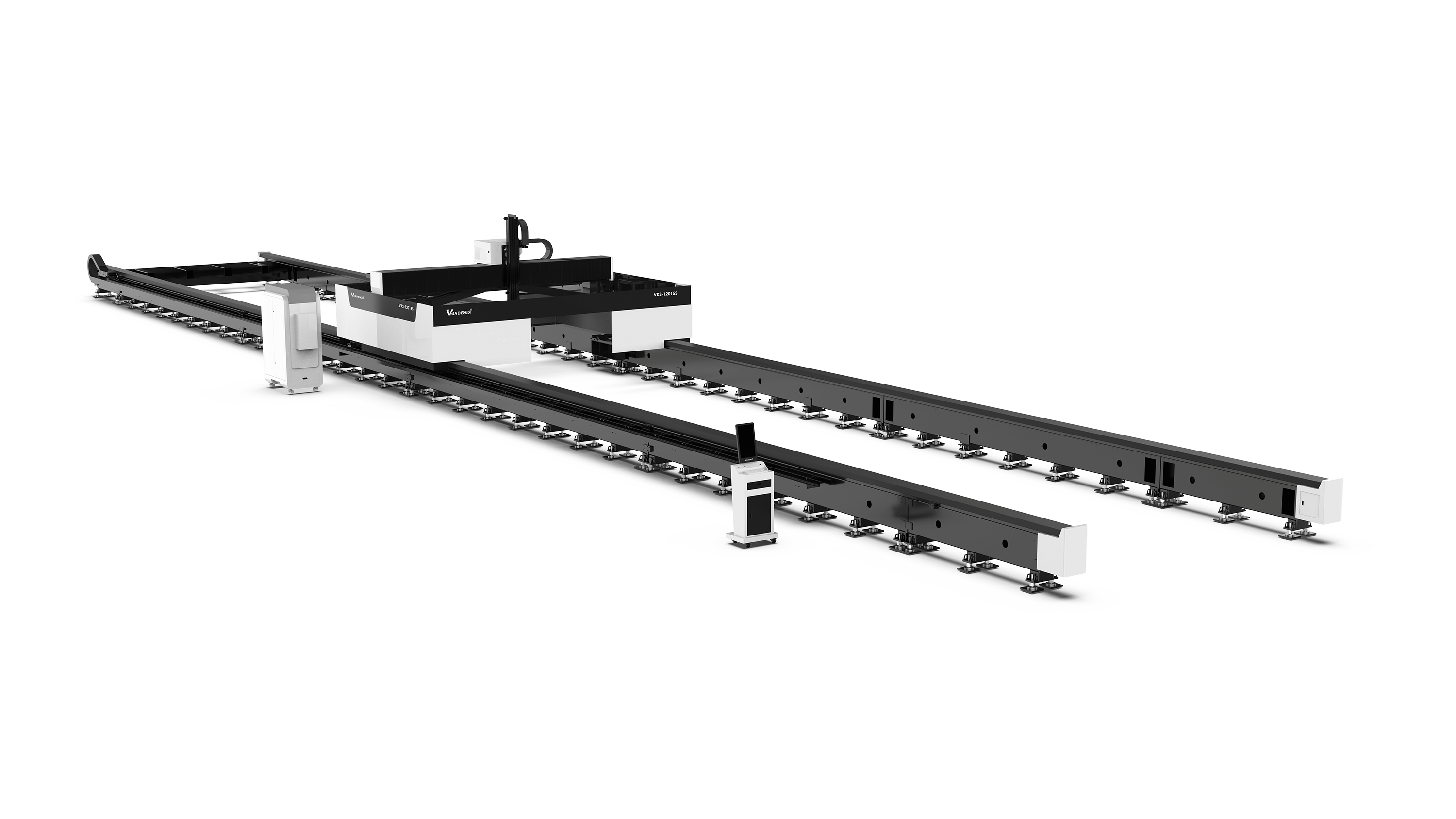

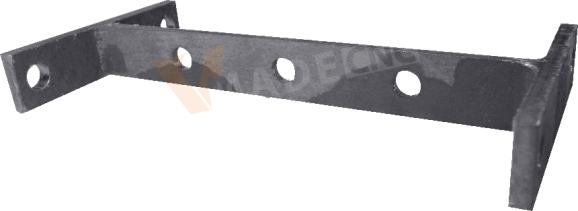

Optional - cutting table for steel profile

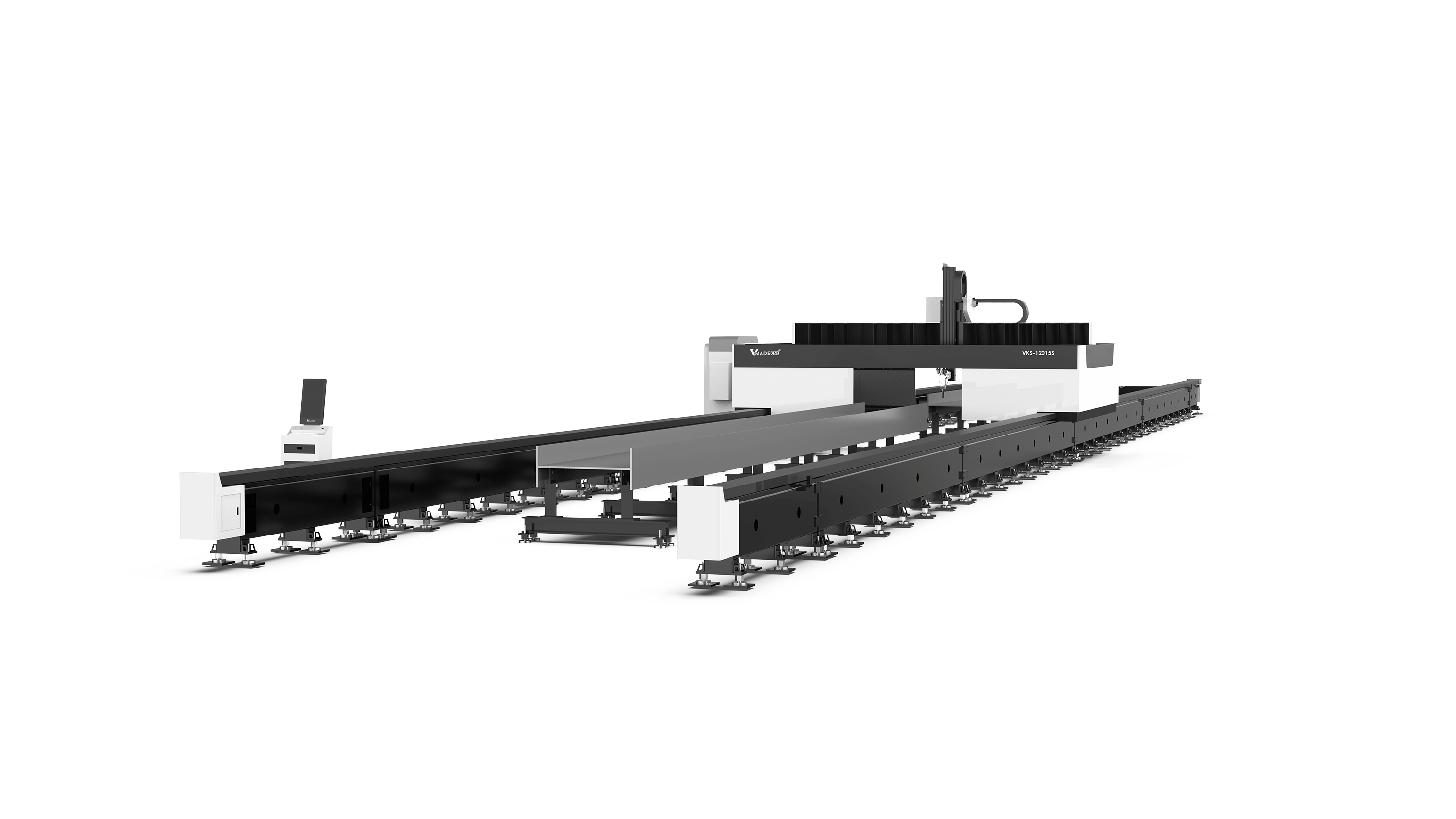

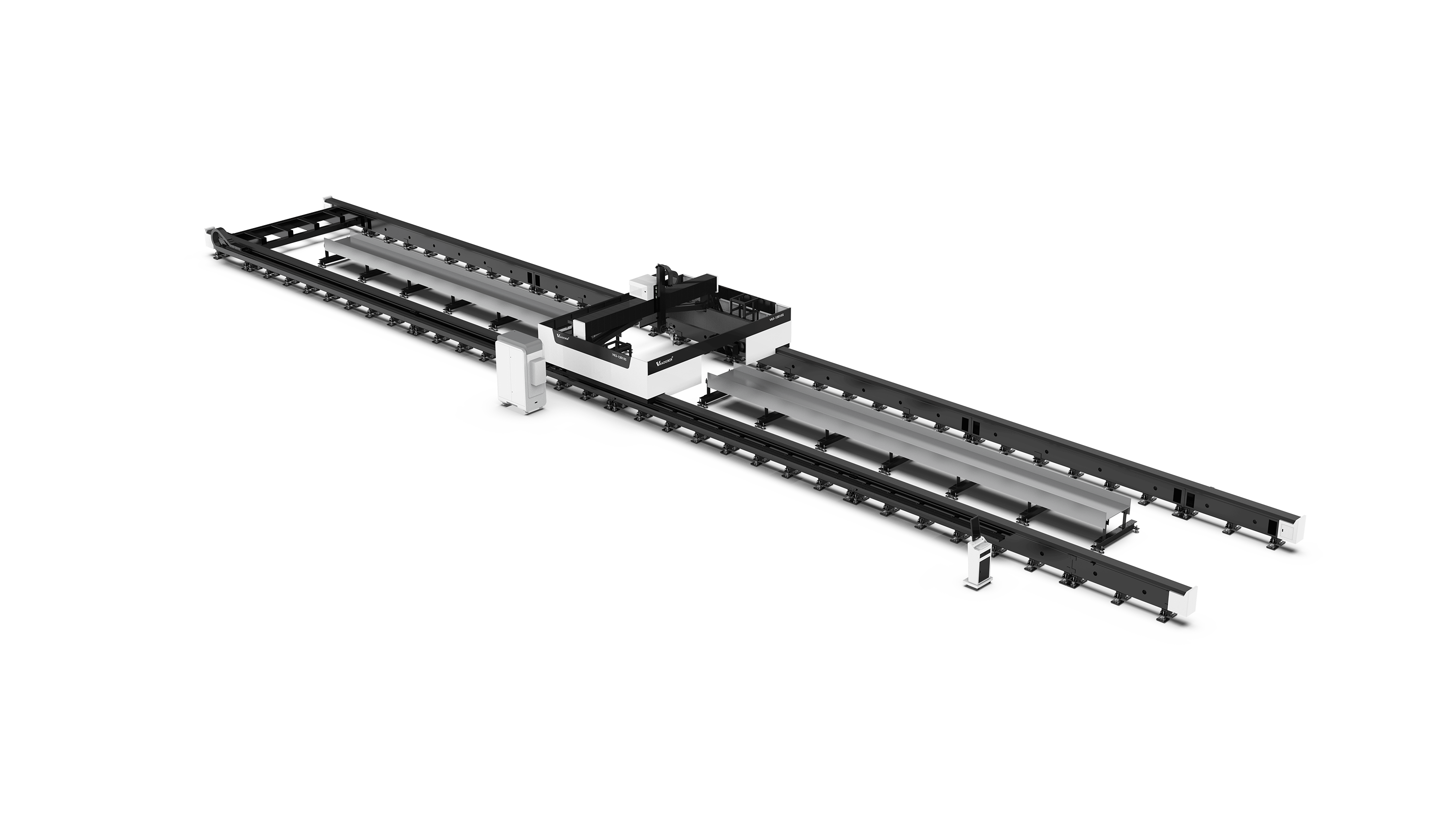

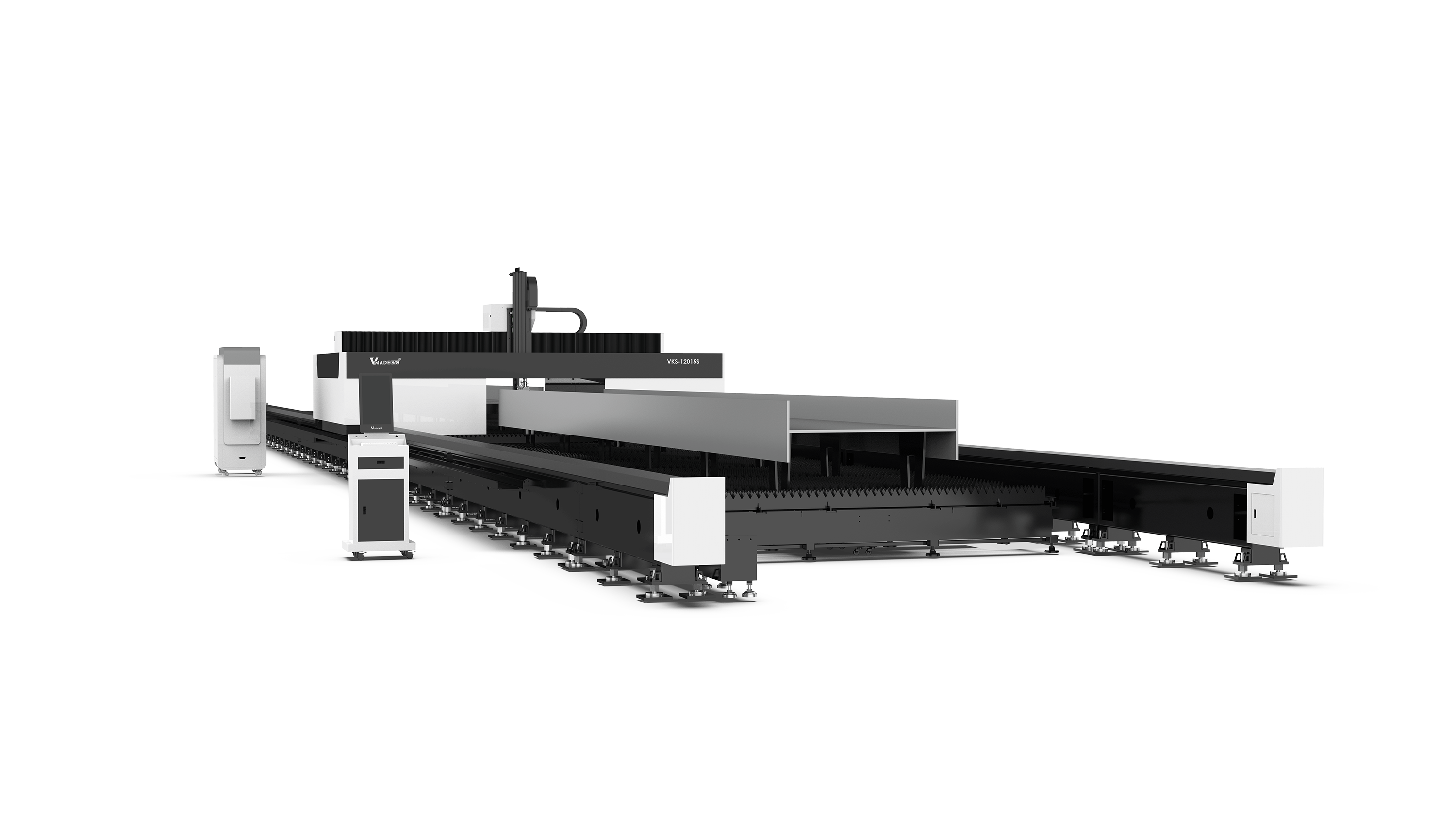

Optional - cutting table for sheet metal & steel profile

EQUIPMENT CHARACTERISTICS

1. Supports both profile and plate processing, consolidating diverse processing requirements into a singular unit.

2. Features a modular design, dual workstations, extending up to 28 meters to accommodate large-format processing demands.

3. Equipped with dual workstations, one station is cutting while the other station is loading and unloading, reducing downtime and enhancing processing efficiency. Simple and easy processing, convenient for loading and unloading.

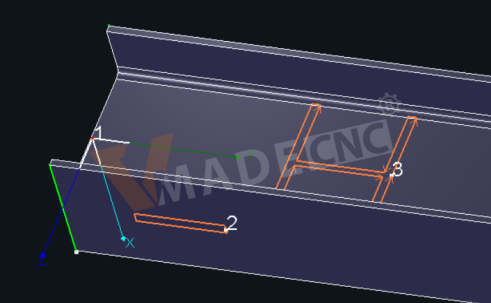

4. A secondary processing production line for steel profile that integrates cutting, hole cutting, beveling, lock joint cutting, marking and scribing processes.

5. Delivers high-precision cutting without excessive grinding, facilitating effortless component assembly and welding, directly solving the problems of low precision and low efficiency of manual processing.

6. Employs three-dimensional five-axis linkage technology for ultra-high efficiency.

7. Adopts a large gantry bed structure, with a static workpiece and mobile gantry processing approach, ensuring a more flexible cutting action.

8. The cutting platform is designed as an independent module from the machine tool, with the weight of the workpiece loaded to the ground. Strong bearing capacity, impact resistance, simplified structure and easy replacement.

9. The process library enables fine hole cutting process.

10. Supports the processing of TEKLA steel structure 3D modeling data files, no need for separate drawing.

11. Supports contour detection, data is transmitted to the processing system in real time, and the deformation area of the steel profile is compensated in real time.

Main Function Introductio

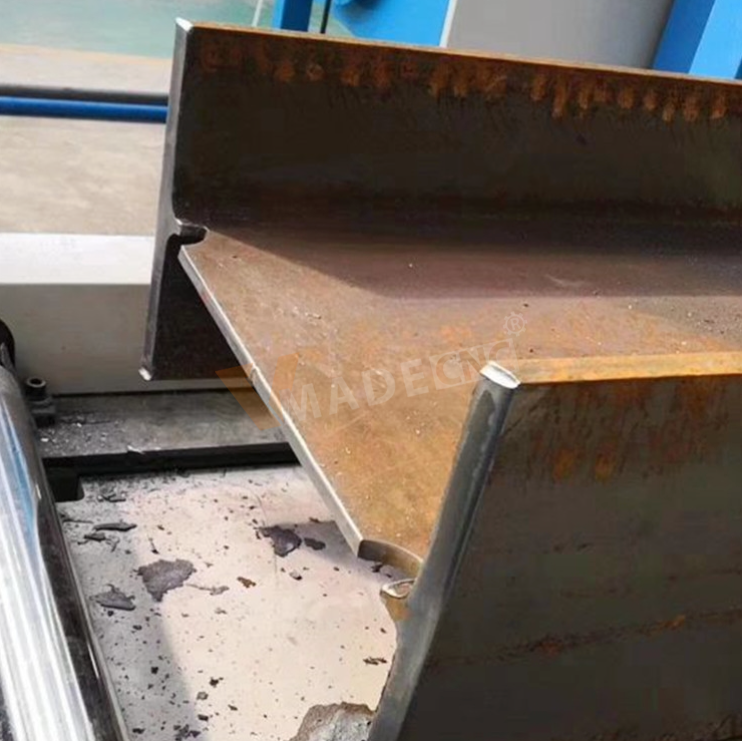

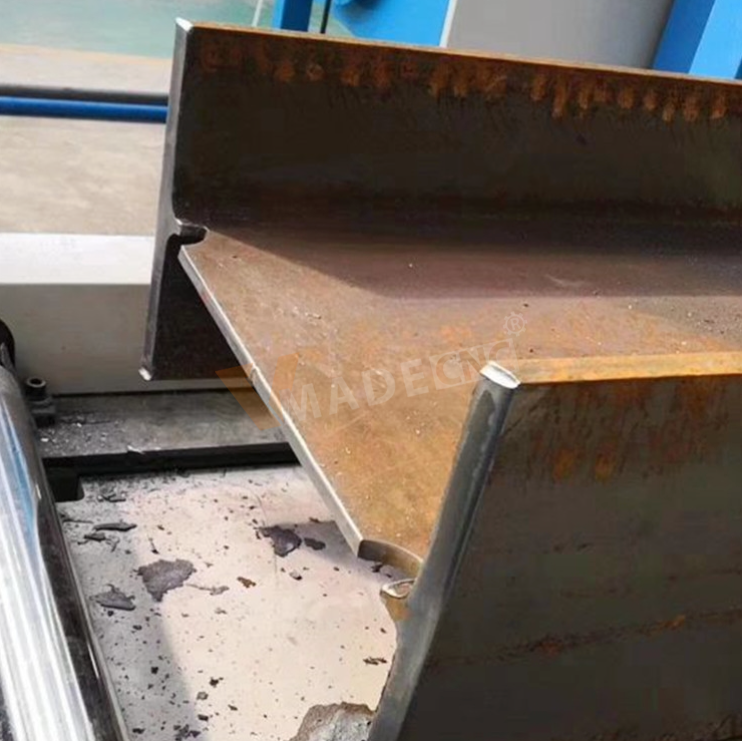

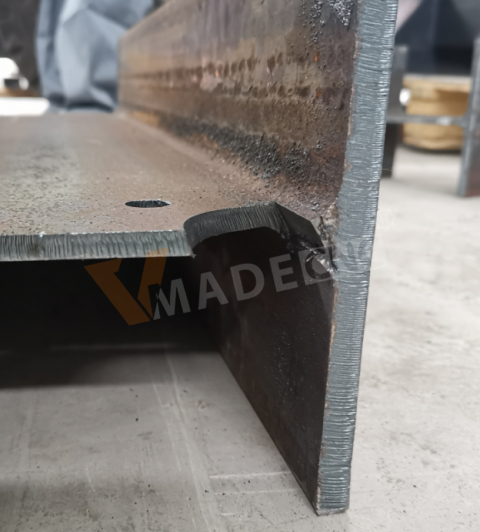

Cutting and beveling

The steel profile is cut out and beveled at one time, which facilitates welding after splicing of the profile steel in subsequent processes, and improves the quality of the profile steel butt weld.

Weld access hole processing

Enables the convenient welding of spliced profile steel, significantly improving the quality of the resulting butt welds.

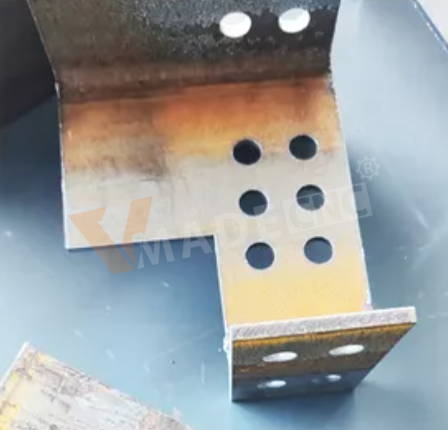

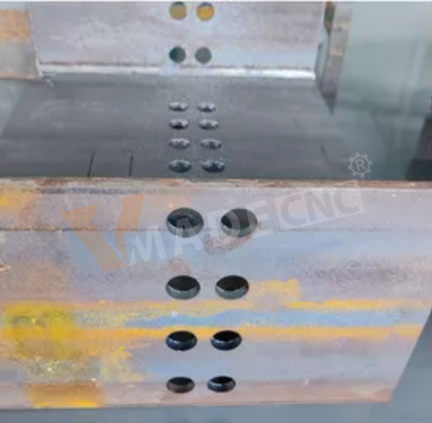

Bolt hole processing

During the splicing of steel profile, bolt holes serve to bear loads, transmit forces and mitigate shocks.

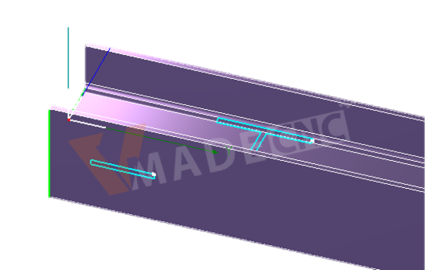

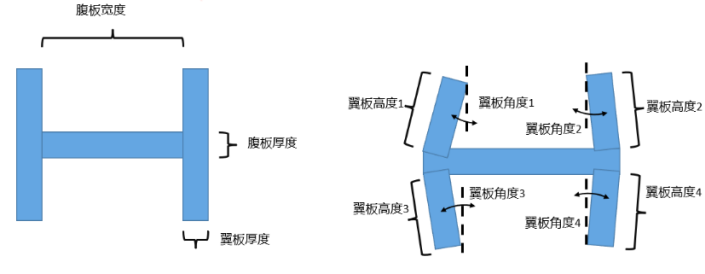

Wing/web bevel processing

The diagonal support of the steel structure enhances its bearing capacity, stability and safety.

Marking positioning

Automatically marks welding positions, reduces riveting processes, and improves component precision

Cutting and locking

Contour Scanning

1) Scans the steel profile before processing, and transmits the data to the processing system in real time.

2) Scans the trajectory to complete point cloud computing in real time, enabling instant modeling, clarification deformation area of steel profile, and real-time compensation.

3) Achieves millisecond-level data transmission, balancing efficiency and accuracy.

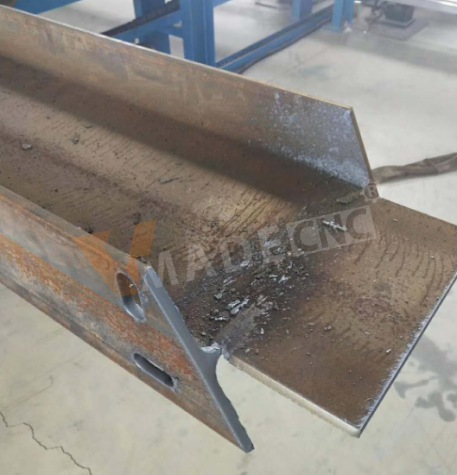

Weld access hole processing

The weld access hole can be cut directly, and through process adjustment, different root retention effects can be cut according to needs.

Bolt hole processing

1) Cutting and punching can be completed in one clamping, with high efficiency

2) Little thermal deformation and high precision

Laser marking

1) Automatically retrieves component names from Tekla.

2) Batch prints to part ends, with high accuracy and efficiency.

3) Automatically marks welding positions.

4) Eliminates the need for manual marking, and save effort in downstream processes.

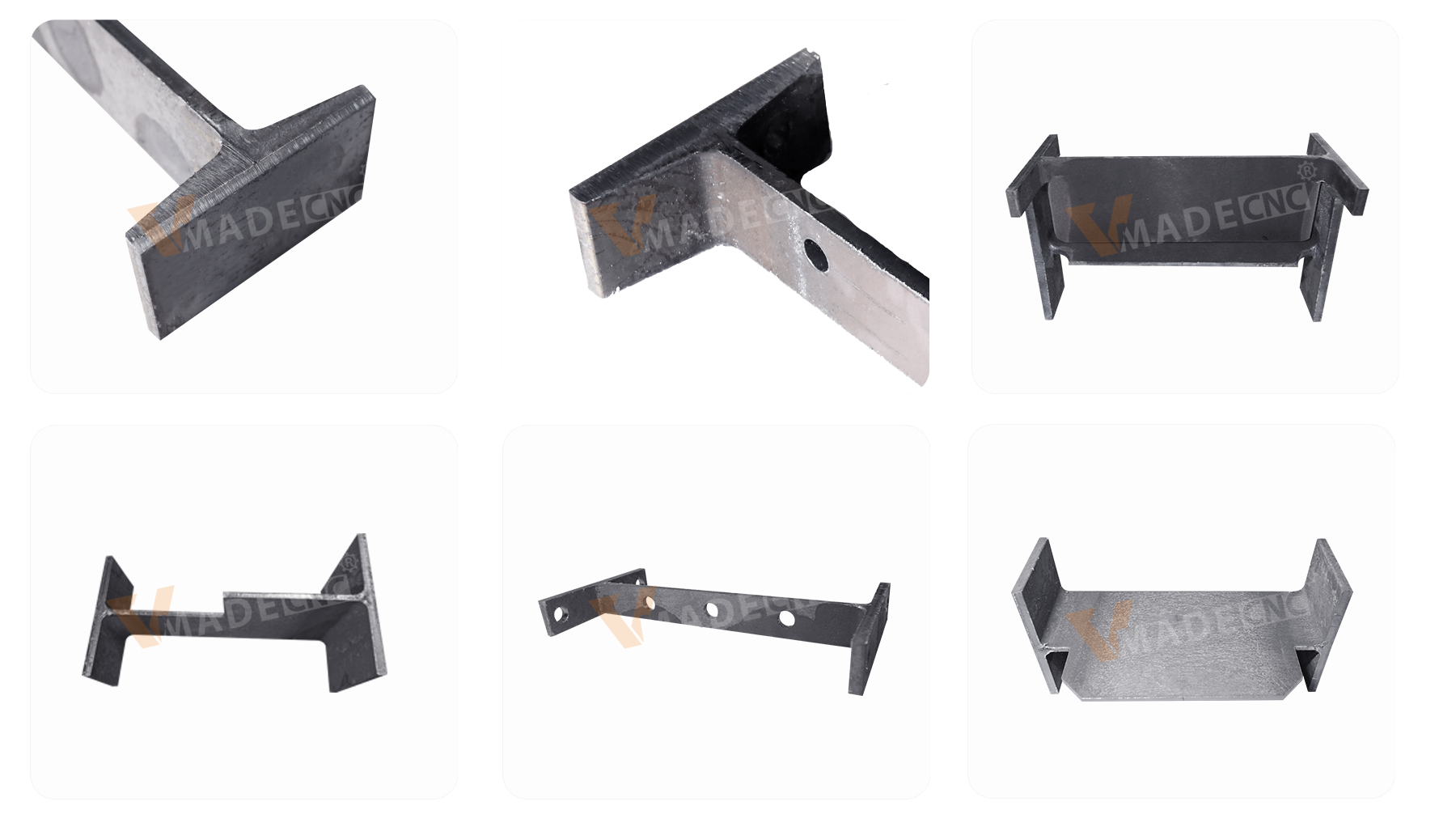

Cutting sample

If you are interested in it, please feel free to contact us.

Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone