Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone

Laser cleaning is an effective method to remove dirt particles and films of different materials and sizes on solid surfaces. Laser cleaning is to form a laser beam with a specific spot shape and energy distribution after optical focusing and spot shaping of a continuous or pulsed laser with high brightness and good directionality. After the contaminant material absorbs the laser energy, it will produce a series of complex physical and chemical processes such as vibration, melting, burning, and even gasification, and finally make the contaminant detach from the surface of the material. Even if the laser acts on the cleaned surface, most All are reflected off, and will not cause damage to the substrate, so as to achieve the effect of cleaning.

A laser cleaning machine is an eco-friendly power cleaning tool for surface treatment with handheld laser cleaning gun or CNC controller. A laser welder is used to remove rust, coatings, paint, oil, oxides, grease, resin, glue, dust, stains, residues, and more surface materials through instant high temperature ablation generated by laser beam on the surface of an object. Laser cleaning machines are also known as laser cleaners, laser rust removal machines, laser rust cleaning machines, laser paint stripping machines, laser paint removal machines, laser coating removal machines, laser oxide removal machines, laser oil cleaning machines, laser dirt cleaning machines, laser descaler machines.

|

|

|

|

| Get Rid of Consumables & Go Green | Eliminate Manual Labor | Minimize Maintenance | Create a Safe Workplace |

| As a green technology, laser cleaning replaces methods that remove rust with consumables or chemicals. It's the only solution that meets environmental protection regulations. Plus, pulsed fiber lasers have low power consumption. | Spending a mass amount of manual labor to clean every single part is inefficient. It is expensive and can be performed more efficiently with robots. Eliminate manual labor through laser cleaning, a technology that can easily be fully or semi-automated. | Everyone who uses abrasive blasting faces the same problem: their machine is constantly interrupted. Laser rust removal is a non-contact method that continuously removes rust while drastically lowering maintenance costs. | Lasers in manufacturing environments are extremely safe when integrated with a dust extraction system and a Class-1 laser safety enclosure, operators who are near the laser system don't need personal protective equipment for respiratory, hearing, or body protection. |

One of the most common uses of laser solutions is removing rust. This is done to prepare for welding or bonding prep, improve efficiencies, or restore products like historic builds to their former glory. The most common metals that can rust, include:

· Iron

· Cast Iron

· Wrought Iron

· Steel

While laser cleaning is an effective means for removing rust, it also works on metals that don't contain iron but still develop an oxide coating. Oxides can alter the integrity of your product and create a protective layer. While this sounds positive, what's actually happening is that your product is breaking down, and removing that oxidation layer will expose it to further deterioration. Laser cleaning not only removes that protective layer, but it also removes the contaminant oxides altogether from your product — protecting it from further damage. The most common metals without iron include:

· Aluminum

· Bronze

· Copper

· Gold

· Platinum

Contaminants such as oxides, grease, mold, and paint can prevent parts from welding or bonding together. This impacts the strength of your product in a big way. Laser cleaning removes even the thickest of contaminants from the surface of your product without impacting the integrity of the substrate — allowing you to secure parts with welding or bonding.

Removing paint can be a long and dangerous process — especially when working with chrome- or lead-based paints. Because laser cleaning uses pulses to absorb and remove contaminants, you can safely remove hazardous paint from your metal applications without creating additional waste or risking the safety of your operators.

Common Laser Cleaning Use Cases For Ceramics:

· Print rollers

· Ceramic molds

· Historical artifacts

· Baking molds

Common laser cleaning use cases for natural stone:

· Restoring stone statuary, ornaments, and other small historical surfaces

· Restoring historic architectural surfaces

· Cleaning stone building facades

· Specialized conservation and restoration

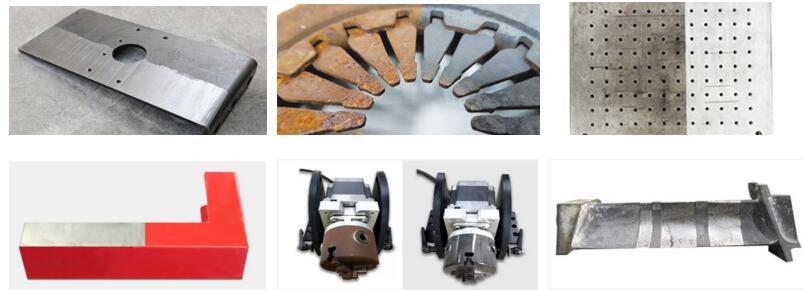

Laser Cleaning Samples

Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone