Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone

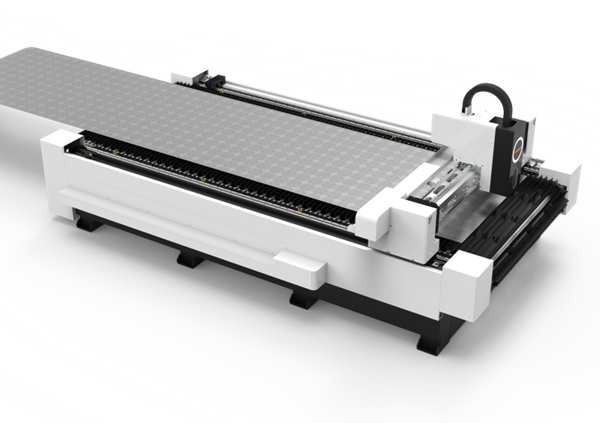

Loading, opening, pressing, cutting | all in one go

The laser sheet uncoiling, leveling, and cutting production line has the function of automatic cut-to-length sheet material, which can unwind, level, and laser cut all kinds of coil materials into different specifications of sheets, and automatically convey the blanking.

Using this line can significantly improve production efficiency, reduce costs, ensure product quality, and improve the market competitiveness of enterprises.

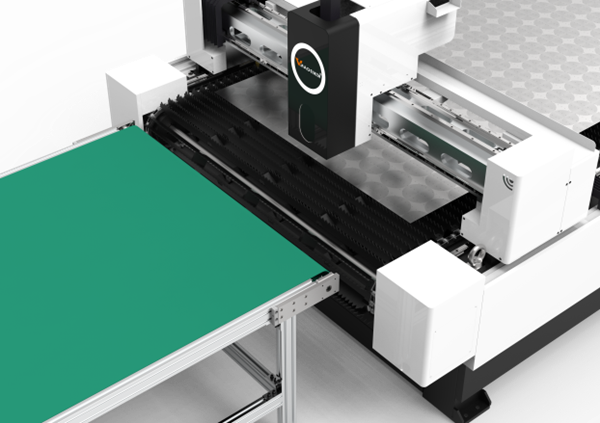

Equipped with a high-precision servo motor, a reliable laser control system, and a high-tech programmable control system to ensure accurate feeding and cutting.

The use of rotatable rolling blades ensures that the conveying of the sheet material can be synchronized with the rotation of the bed during the cutting process. The double-sided chain transmission mode is adopted to ensure that the force on both ends of the rolling blade is even, the bed is more stable when running, and the cutting accuracy is improved.

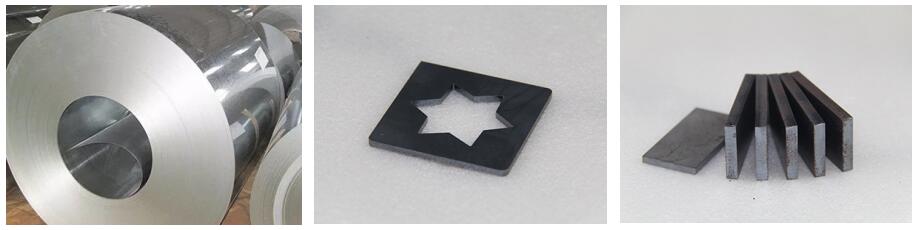

It can be specially used for 0.5-25mm carbon steel plate, 0.5-16mm stainless steel plate, galvanized plate, cold rolled plate, electrolytic plate, 05-16mm aluminum alloy plate, 0.5-10mm brass and copper and other metal materials.

Widely used in many industries such as auto parts, kitchen, and bathroom hardware, electrical and electronic, and smart home.

This coil production line breaks through the limit of the ordinary laser cutting length and has subversive significance in some fields. It can save labor costs and greatly improve production efficiency. It has truly realized the automatic cutting of the assembly line, please consult us for more details!

Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone