Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone

A: We choose a high-quality Q235 steel plate, one plate thickness of at least 10mm. which is more suitable for heat treatment, with high comprehensive performance, easy to weld; high toughness, not easy to break, and high thermal strength. the cost is higher than normal material.

B: All of our welding engineers have more than ten years of rich experience. They can accurately pinpoint the stress points and weld accurately so that the steel plate is less heated and deformed. In welding, our welding step is to weld the outer frame of the bed first, and then fill the horizontal steel plate inside. This operation can minimize the amount of deformation. But it will cost too much time.

C: This is the most important step in the formation of a good bed. We will conduct a heat treatment operation for at least 10 hours; in this process, the four corners of the bed will be flattened to make it more fit to the ground and the bed will be more stable; then let the bed cool naturally for at least 20 hours. Eliminate stress, and ensure the stability and non-deformability of the bed.

D: After high-temperature annealing, an oxide layer will be formed on the surface of the bed. We will perform sandblasting, sanding, rust removal, primer spraying, and second painting to prevent the bed from growing. rust. Longer service life.

E: A milling machine is used for gantry milling to ensure the accuracy of the machine tool. First, we will rough machining again, and then let it rest naturally for 20 hours to release the stress, so that the stress can be released to the greatest extent, and then finish machining again until it reaches the accuracy we specified.

Light - Light in weight with excellent beam dynamics.

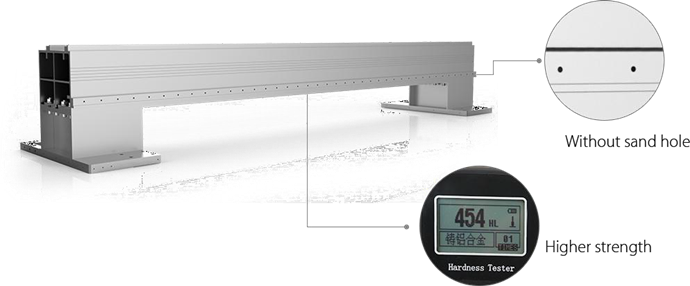

Solid - manufactured by aerospace standards, extruded with 4300 tons of pressure.

After strong-aging treatment, the hardness can reach T6, which is the strongest among all beams. Strong, with good toughness and ductility, good rigidity, and high strength

4th Generation Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons of press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, lightweight, corrosion resistance, anti-oxidation, low density, and greatly increase processing speed.

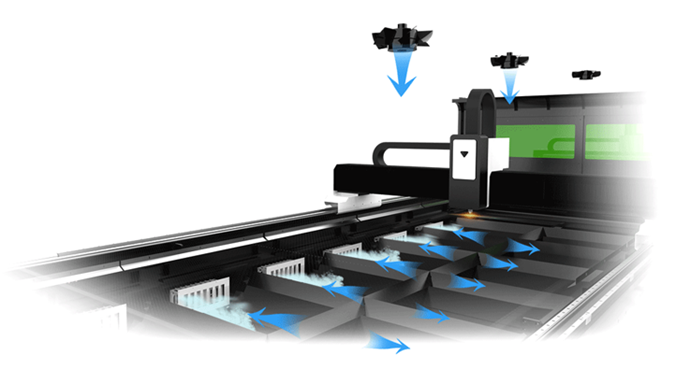

All electrical components and lasers are placed in the control cabinet, excellent dustproof design, improves the life of electrical components.

Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone